MZ-Tech All Electrical Vertical Moulding Machine: Overview

The MZ-Tech All Electrical Vertical Moulding Machine is a cutting-edge solution designed for precision molding applications, combining advanced technology with energy-efficient operation. This machine is engineered to meet the high demands of the manufacturing industry, offering a reliable and eco-friendly alternative to traditional hydraulic molding systems.

Key Features:

- All-Electric Drive System: Unlike conventional machines that on the hydraulic oil, the MZ-Tech vertical molding machine is powered entirely by an electric drive. This ensures greater energy efficiency, reduced maintenance costs, and improved operational precision.

- Vertical Molding Design: The vertical molding configuration allows for efficient space utilization and ease of mold handling. It is particularly suited for applications requiring consistent molding quality and high-volume production.

- Energy Efficiency: The all-electric design significantly reduces power consumption compared to hydraulic counterparts, making it an environmentally friendly choice for manufacturers looking to lower their energy footprint.

- High Precision & Consistency: The MZ-Tech machine is equipped with advanced servo motors and control systems, offering exceptional precision in the molding process. This results in consistent product quality and reduced material waste.

- User-Friendly Interface: The machine is equipped with an intuitive control system, making it easy for operators to set up, monitor, and adjust molding parameters. This user-friendly interface reduces training time and enhances operational efficiency.

- Low Maintenance & Durability: With fewer moving parts and the absence of hydraulic fluids, the MZ-Tech vertical molding machine requires less maintenance and offers a longer lifespan compared to traditional molding machines.

- Versatility: Suitable for a wide range of applications, including automotive, electronics, and consumer goods manufacturing, the MZ-Tech machine is adaptable to various mold designs and materials.

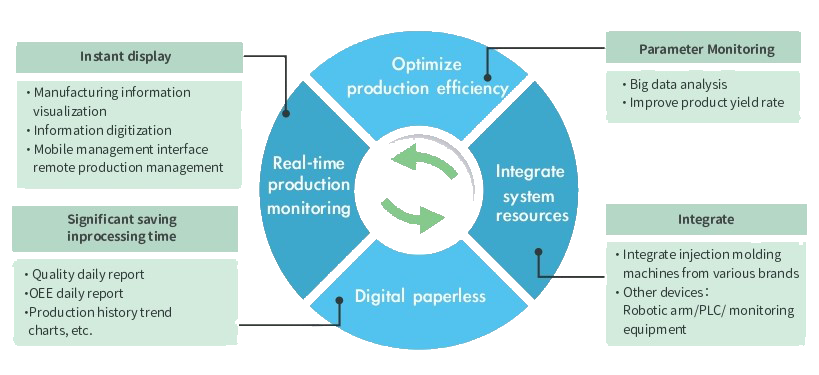

1. Quickly set up and easily connect production equipment.

2. Collect data

3. Provide real-time information and report.

4. Intelligent production management, data-based parameter analysis and application.

5. Data visualization, production management panel can be adjusted according to needs and permissions.

6. Integrate equipment from different brands for senes production and simplily production management work.

7. Relevant data can be provided to remote devices for monitoring or reference.